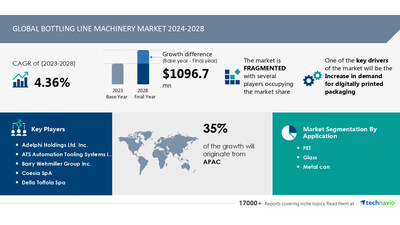

NEW YORK , Sept. 18, 2024 /PRNewswire/ — Report on how AI is driving market transformation- The global bottling line machinery market size is estimated to grow by USD 1.1 billion from 2024-2028, according to Technavio. The market is estimated to grow at a CAGR of almost 4.36% during the forecast period. Increase in demand for digitally printed packaging is driving market growth, with a trend towards innovations in bottling line machinery. However, influence of smes in bottling industry leading to risks poses a challenge. Key market players include Adelphi Holdings Ltd. Inc., ATS Automation Tooling Systems Inc., Barry Wehmiller Group Inc., Coesia SpA, Della Toffola Spa, EDL Packaging Engineers Inc., GEA Group AG, Mpac Group Plc, PallayPack Inc., Pro Mach Inc., Salzgitter AG, Syntegon Technology GmbH, Tetra Laval SA, and Uhlmann Pac Systeme GmbH and Co. KGA.

Key insights into market evolution with AI-powered analysis. Explore trends, segmentation, and growth drivers- View the snapshot of this report

Bottling Line Machinery Market Scope

Report Coverage

Details

Base year

2023

Historic period

2018 – 2022

Forecast period

2024-2028

Growth momentum & CAGR

Accelerate at a CAGR of 4.36%

Market growth 2024-2028

USD 1096.7 million

Market structure

Fragmented

YoY growth 2022-2023 (%)

4.11

Regional analysis

APAC, Europe, North America, South America, and Middle East and Africa

Performing market contribution

APAC at 35%

Key countries

China, US, Germany, UK, and Japan

Key companies profiled

Adelphi Holdings Ltd. Inc., ATS Automation Tooling Systems Inc., Barry Wehmiller Group Inc., Coesia SpA, Della Toffola Spa, EDL Packaging Engineers Inc., GEA Group AG, Mpac Group Plc, PallayPack Inc., Pro Mach Inc., Salzgitter AG, Syntegon Technology GmbH, Tetra Laval SA, and Uhlmann Pac Systeme GmbH and Co. KGA

Market Driver

The bottling line production sector is experiencing significant growth due to increasing consumer demands for diverse products. Manufacturers are investing in flexible equipment to accommodate various product types, such as Bosch’s Ampack carousel filling machine for milk and dairy products. Sidel’s new Sidel StarLite Nitro version PET bottle uses nitrogen dosing production lines for enhanced bottle stability and resistance to pressure. Innovations like Krones’ ErgoBloc LC KT, a proportional flow regulator, and Contiroll gluing station, increase efficiency, capacity, and high-speed production. Compliance with safety regulations and the use of Ethernet for communication between bottling line machinery components further boosts market opportunities. With features like increased efficiency, capacity, and high-speed production, multi-functional bottling line machinery systems are in high demand. These systems not only meet safety regulations but also contribute to energy and resource savings. The adoption of innovative technologies, such as those mentioned above, is expected to drive the future growth of the global bottling line machinery market. (Exact word count: 50)

The Bottling Line Machinery Market is experiencing significant trends in various sectors. In beverages, precision filling mechanisms, automated capping systems, labeling, and quality control sensors are popular. Sanitation measures and touchless technologies ensure hygiene and safety. Digital twin technology, simulation, and automation technologies like robotics and artificial intelligence are driving Industry 4.0. Sustainability is a key focus with PET, glass, metal cans, and aluminum bottles. Smart manufacturing techniques and hygienic design features are essential for soft drinks, juices, bottled water, and beverage products. Contract manufacturing for healthy beverages, sports drinks, low-calorie drinks, nutritional drinks, and private label brands is on the rise. Automatic technology is preferred in chemical manufacturing plants for handling flammable and inflammable liquids and organic solvents. Retraining programs and routine maintenance tasks ensure optimal performance. Smart features are increasingly important for cloth wardrobes and processed food products in the semi-automatic segment.

Request Sample of our comprehensive report now to stay ahead in the AI-driven market evolution!

Market Challenges

The bottling line machinery market is characterized by intense competition due to the presence of numerous small and medium-sized enterprises (SMEs). Manufacturers face pressure to provide affordable bottling line machinery while maintaining profitability and quality standards. Large companies often secure fixed-price contracts, potentially leading to additional costs for vendors. Raw material costs, particularly for aluminum and steel, fluctuate due to economic and geopolitical factors, posing challenges. Advanced bottling line machinery development necessitates significant capital investments for automated solutions, which may be prohibitive for cost-conscious players, potentially hindering market growth. The Bottling Line Machinery Market faces several challenges in various sectors. Inorganic solvents and acidities require specialized machinery for handling. Alcoholic products, beverages, medicines, and cleaning supplies call for different viscosities and temperatures. The geriatric population and disease incidences necessitate the production of lightweight packaging for beverages and ready-to-drink products. Manufacturing machines for liquids in beverage manufacturing plants, such as wine, soft drink manufacturers, and prepared food, must be flexible to accommodate various product types. Semi-automatic technology is crucial for cosmetics and personal care. Challenges include managing the production of functional beverages, digitalization, data analytics, and sustainable materials. Industrial automation through PLCs, SIG, Liquibox, Syntegon, Bayer, and others is essential for efficient bottle cleaning, filling, and packaging. Government incentives and support for sustainable materials and industrial automation are vital for the market’s growth. The market includes glass, plastic, and metal bottling lines, catering to various industries like beverages, medicines, and chemicals. Bag-in-box filling and aseptic carton packaging are also significant trends. Discover how AI is revolutionizing market trends- Get your access now!

Segment Overview

This bottling line machinery market report extensively covers market segmentation by

Application 1.1 PET 1.2 Glass 1.3 Metal can Technology 2.1 Automatic 2.2 Semi-automatic Geography 3.1 APAC 3.2 Europe 3.3 North America 3.4 South America 3.5 Middle East and Africa 1.1 PET- The PET bottling industry is experiencing significant growth due to the widespread use of PET in packaging beverages, healthcare, and household care products. PET’s physical properties, such as its ease of molding, make it a popular choice for manufacturers. The market for bottling line machinery is driven by the increasing demand for PET bottles, particularly in the beverage industry, where single-serve drinks are gaining popularity. Additionally, the emergence of biodegradable plastics is expected to further fuel market growth. However, challenges such as sustainability concerns and regulatory restrictions, including the FDA’s regulations on PET bottle sizes, may hinder market expansion.

Download a Sample of our comprehensive report today to discover how AI-driven innovations are reshaping competitive dynamics

Research Analysis

The Bottling Line Machinery Market is witnessing significant growth due to the increasing demand for beverages, both healthy and conventional, and processed food products. Automatic technology is driving the market with its ability to increase production efficiency and reduce human error. The market caters to various industries, including beverage manufacturing plants for soft drinks, wine, and medicines. Contract manufacturing is also a significant contributor to the market’s growth. The market comprises various machinery, including manufacturing machines for liquids, bottle cleaning systems, filling machines with precision filling mechanisms, capping systems, and automated labeling machines. The market also offers cleaning supplies and single-serve packaging solutions for PET bottles. Quality control sensors ensure the production of high-quality beverages and medicines. The semi-automatic segment is also gaining popularity due to its cost-effectiveness.

Market Research Overview

The Bottling Line Machinery Market encompasses various types of machinery used in the production and packaging of beverages, processed food products, and other liquids. The market caters to the demands of beverage segments, including healthy beverages, sports drinks, low-calorie drinks, nutritional drinks, and alcoholic products. Contract manufacturing and automatic technology dominate the industry, with semi-automatic machinery also holding a significant share. The market serves various industries, including beverage manufacturing plants, chemical manufacturing plants, and wine producers. The market is influenced by factors such as the geriatric population’s increasing disease incidences, rising beverage consumption, and the trend towards sustainable materials and lightweight packaging. The market includes various types of machinery, such as filling, capping, labeling, and precision filling mechanisms. The industry is also witnessing digitalization, with the adoption of sensors, real-time monitoring, and automation technologies like robotics and artificial intelligence. The market comprises various types of packaging, including PET, glass, and metal cans, and serves industries such as medicines, cleaning supplies, cosmetics, and personal care. The market is also influenced by government support, incentives, and industrial automation technologies like PLCs, SIG, and aseptic carton packaging. The market’s future growth is expected to be driven by factors such as sustainability, Industry 4.0, and the increasing demand for functional beverages.

Table of Contents:

1 Executive Summary

2 Market Landscape

3 Market Sizing

4 Historic Market Size

5 Five Forces Analysis

6 Market Segmentation

Application PET Glass Metal Can Technology Automatic Semi-automatic Geography APAC Europe North America South America Middle East And Africa 7 Customer Landscape

8 Geographic Landscape

9 Drivers, Challenges, and Trends

10 Company Landscape

11 Company Analysis

12 Appendix

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 17,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

Contacts

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email: media@technavio.com

Website: www.technavio.com/

View original content to download multimedia:https://www.prnewswire.com/news-releases/bottling-line-machinery-market-to-grow-by-usd-1-1-billion-from-2024-2028–driven-by-rising-demand-for-digitally-printed-packaging-ai-powered-report–technavio-302252128.html

SOURCE Technavio

Leave a Reply